Food waste costs businesses millions each year. A Food Depackager can save so much on that cost that buying one and using it can easily be worth the investment. Many companies struggle to separate food from packaging, leading to higher disposal fees and lost profits. The mix of food and packaging, plus a limitless range of unwanted items uncaringly dumped into the food waste bin, creates a mess that’s hard to handle.

This problem affects both small shops and large food makers.

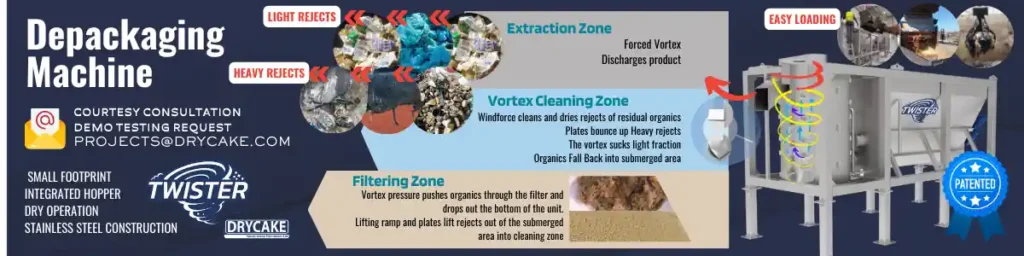

The latest food waste depackaging systems offer a smart fix. These machines pull apart food from its wrapping, making recycling easier. They no longer mill and crush it into tiny plastic pieces that may be causing human disease. They can process loads of waste quickly and cut labour costs.

The best part? These systems help companies save money while helping the planet.

Want to know if a depackaging system fits your budget? We’ll break down all the costs and savings you need to know. From buying the machine to daily running costs, we’ll show you the real numbers that matter.

Ready to learn more about making waste work for you?

Key Takeaways

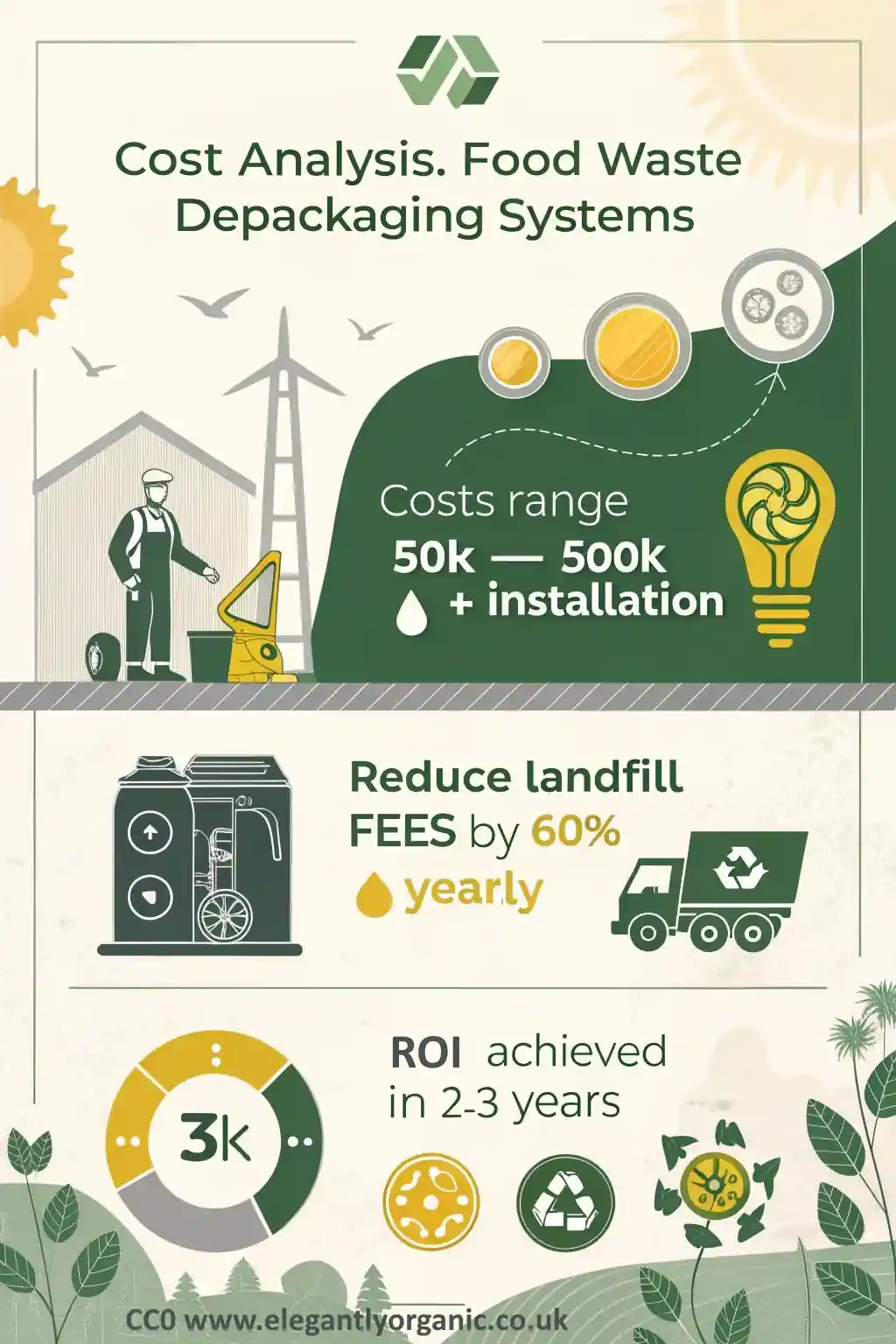

- Food waste depackaging systems cost between £50,000 to £500,000, with installation adding 15-25% to total costs. Small units process 2-3 tonnes hourly, while large systems handle up to 15 tonnes per hour.

- Operating costs include energy usage (30-75 kilowatts per hour), maintenance (parts replacement every 3-6 months), and labour (2-3 workers for small systems, 5-6 for larger ones). Staff wages range from £25,000 to £35,000 yearly in the UK.

- Companies can reduce landfill fees by up to 60%, saving £15,000 to £25,000 yearly. The systems create revenue through selling organic pulp, clean plastics, and RDF/RSF products. One facility generates £500,000 yearly from 5,000 tonnes of food waste rejects.

- Modern depackaging systems cut manual sorting time by 80% and reduce machinery downtime by 40%. The UK government offers up to 40% tax relief on green technology investments, plus local council grants between £5,000 to £50,000 for waste reduction projects.

- Businesses typically recover their investment within 2-3 years through operational savings and government incentives. Companies report up to 15% growth in customer satisfaction scores after implementing these systems.

Importance of Cost Analysis for Food Waste Depackaging Systems

Cost analysis plays a vital role in making smart choices about food waste depackaging systems. Business leaders need clear facts about expenses and profits before spending money on these machines.

A proper cost study helps companies spot hidden fees and calculate their possible returns. Smart managers look at both short-term and long-term money matters to make the best choice for their needs.

Smart financial planning in waste management isn’t just about counting pennies – it’s about creating sustainable value for tomorrow.

The right depackaging system can save money through lower disposal fees and extra income from selling materials. Companies must check energy bills, repair costs, and worker wages to get the full picture.

These systems affect the bottom line in many ways, from cutting landfill costs to making money from organic waste. A thorough cost review helps businesses pick the perfect system size and type for their budget and goals.

Types of Costs Involved

Money matters in food waste depackaging systems split into two main groups. Each cost type plays a vital role in the success of your waste management programme, from the first big spend to the daily running costs.

Initial Investment Costs

Food waste depackaging systems need a big upfront investment. The purchase price of these machines ranges from £50,000 to £500,000, based on their size and processing power. Large-scale industrial units cost more than smaller ones due to their advanced features and higher capacity.

Installation charges add another 15-25% to the total cost, which includes site preparation, electrical setup, and safety measures.

The machine’s make and model play a vital role in the total investment cost. Top brands like Haarslev and BTA International offer systems with different processing speeds and separation efficiency.

A basic model processes 2-3 tonnes per hour, while advanced versions handle up to 15 tonnes hourly. The installation process takes 3-5 days and needs skilled technicians. Smart buyers look at factors like energy usage, maintenance needs, and spare parts availability before making their choice.

Ongoing Operational Costs

Beyond the upfront costs of depackaging systems, daily running expenses need careful planning. Operating costs shape the long-term success of these waste management solutions. Energy bills, staff wages, and regular maintenance form the core expenses that impact your bottom line.

Smart operational planning today leads to sustainable savings tomorrow.

The costs of running a depackaging system break down into four main areas. Energy usage varies based on machine size and daily runtime hours. Maintenance costs cover regular parts replacement and emergency repairs.

Labour expenses depend on the number of workers needed to run the system. Disposal fees apply to materials that can’t be recycled or processed. These costs change based on local utility rates, worker wages, and disposal regulations in your area.

Initial Investment Costs

Setting up a food waste depackaging system needs careful money planning from the start. The price tag includes the machine cost, setup fees, and building changes, which can range from £50,000 to £500,000 based on your needs.

Purchase Price of Depackaging Machine

Food waste depackaging machines cost between £50,000 to £500,000 in today’s market. The price varies based on the machine’s size, processing speed, and brand reputation. Small units that handle 2-3 tonnes per hour sit at the lower end of this range.

Large industrial systems that process 15-20 tonnes hourly command premium prices at the top end.

Machine capacity plays a major role in determining the final cost. Basic models separate only dry packaged foods, while advanced systems handle wet and dry materials with 99% recovery rates.

Top manufacturers like Haarslev and BTA International offer machines with different power ratings, from 30kW to 110kW motors. These specs directly affect the purchase price and running costs.

The right choice depends on your daily waste volume and budget limits.

Variation in Prices Based on Size, Make, Model, and Capacity

Price variations in depackaging systems reflect their operational capabilities and manufacturing specifications. Let’s examine the cost differences across various machine categories.

| Machine Category | Capacity Range (tonnes/hour) | Price Range (£) | Key Features |

|---|---|---|---|

| Small-scale Units | 0.5 – 2 | 50,000 – 150,000 | Basic separation, manual loading, single-phase power |

| Medium-scale Units | 2 – 5 | 150,000 – 400,000 | Automated loading, dual separation stages, remote monitoring |

| Large-scale Units | 5 – 15 | 400,000 – 900,000 | Full automation, multiple separation stages, advanced controls |

| MRF (Mechanical Recycling Facilities) with integrated Depacking and Separation Units | 15+ | 900,000+ | Continuous operation, integrated sanitising, AI-powered sorting |

Machine prices shift based on manufacturer reputation and country of origin. European manufacturers often command premium prices. Asian alternatives offer competitive rates. North American models balance cost and quality considerations. Advanced features like automatic sorting and sanitising functions raise costs significantly.

Next, we’ll explore the crucial installation charges that impact total investment costs.

Consideration of Installation Charges

Installation charges pack a hefty punch to your budget. Site preparation needs proper electrical wiring, plumbing systems, and structural modifications. These costs often match or exceed the machine’s price tag.

A top food waste depackaging system needs specific power requirements, water connections, and drainage systems for smooth operations.

Smart planning for installation costs today saves double tomorrow – Marcus Chen, Waste Management Expert

The setup process demands skilled technicians and specialised equipment. Labour costs for installation vary by location and system complexity. Most suppliers charge £5,000 to £15,000 for basic installation services.

Extra fees apply for custom modifications or challenging site conditions. Many companies miss these hidden costs in their initial budget plans. Your site might need upgrades to meet safety standards or local regulations.

Smart planners factor in these expenses from day one.

Ongoing Operational Costs

Running a food waste depackaging system takes more than just buying the machine – you’ll need to plan for daily power bills, regular tune-ups, staff wages, and waste removal fees, but stick around to learn how these costs can turn into savings!

Energy Consumption Costs

Energy costs make up a big part of running food waste depackaging systems. Most machines need 30-75 kilowatts per hour to separate food from packaging. The exact power use depends on the machine’s size and how much waste it processes.

A medium-sized system that runs 8 hours daily can add £500-£1,000 to monthly electricity bills.

Smart power management helps cut these costs significantly. Modern depackaging systems come with energy-saving modes that reduce power use during low-volume periods. The latest models use up to 40% less electricity than older versions through better motors and improved separation technology.

Many facilities offset these expenses by selling recovered materials and organic matter for biogas production.

Maintenance and Repair Expenses

Maintenance costs for food waste depackaging systems need careful planning. Your machine parts face daily wear from processing mixed materials. Regular upkeep stops small issues from growing into big problems.

Most systems need monthly checks of critical components like bearings, seals, and filters. These parts often need replacement every 3-6 months, based on usage levels.

Prevention costs pennies, but repairs cost pounds – Industry maxim

The repair budget must cover both planned and sudden fixes. Parts replacement makes up 60% of repair costs, while labour takes the other 40%. Smart operators keep spare parts on hand to reduce downtime.

A good maintenance plan helps predict yearly costs better. Labour expenses for maintenance tasks vary by region and skill level needed. The next key cost factor to consider is the energy needed to run these systems daily.

Labour Costs

Beyond repair costs, staff wages form a major part of depackaging operations. Labour costs vary based on the system’s automation level. Basic systems need more workers to sort materials and monitor operations.

Modern automated systems cut labour needs by up to 70%, but still require skilled operators to run them.

The staff expense depends on your facility’s size and operating hours. A single shift needs 2-3 workers for small systems, while larger operations might need 5-6 workers per shift.

Each worker’s pay ranges from £25,000 to £35,000 yearly in the UK. Smart companies balance automation with labour to keep costs low. Training staff to handle both routine tasks and minor fixes helps reduce overall expenses.

Disposal Fees

Disposal fees make up a big part of waste management costs. Local councils charge different rates to process packaging materials from food waste. These fees depend on the type and amount of waste materials.

Smart companies now use depackaging systems to cut these costs. The systems separate food waste from packaging, which leads to lower disposal charges.

Most waste facilities charge by weight or volume for different waste types. Food-soaked packaging costs more to dispose of than clean, separated materials. The fees vary across regions based on local rules and available disposal sites.

Many facilities charge extra for mixed waste that needs more sorting. Companies can save money by removing food from packaging before disposal. This practice helps create recyclable materials and reduces landfill fees.

Potential Savings and Revenues from Food Waste Depackaging Systems

Food waste depackaging systems offer clear money-making chances through multiple streams. Smart businesses can earn from selling organic pulp, clean plastics, and other sorted materials while cutting their waste disposal costs at the same time.

Reduced Waste Volume

Modern depackaging systems slash waste volumes by up to 80% through smart separation. These machines pull apart packaged food waste into clean, useful parts. The organic material goes to biogas plants or composting sites.

The plastic, metal, and glass move to recycling centres. This split creates less rubbish for landfills and more materials for reuse.

Businesses save big money on waste disposal fees with smaller waste volumes. A typical food factory can cut its monthly waste bills by half after installing a depackaging system. The separated organic matter helps make renewable energy or rich compost.

The clean packaging materials bring in extra cash through recycling. Smart waste sorting leads to both environmental and financial wins.

Lower Landfill Disposal Fees

Food waste depackaging systems slash landfill fees by up to 60%. Companies save big money through reduced waste volumes and smart disposal methods. The organic pulp goes straight to anaerobic digestion facilities instead of landfills.

This cuts transport costs and disposal charges in half. Most facilities report £15,000 to £25,000 in yearly savings on landfill fees alone.

Businesses benefit from lower tipping fees at waste management sites. The separated packaging materials create new revenue streams through recycling. Clean plastic, metal, and glass fetch good prices in the recycling market.

Local councils offer tax breaks for companies that reduce their landfill waste. These savings add up fast for food manufacturers and retailers who process large volumes of expired products.

Potential Revenue from Selling Organic Pulp for

Organic pulp from depackaging systems creates valuable revenue streams for businesses. Companies can sell this nutrient-rich material to farmers as natural fertiliser, replacing costly chemical alternatives.

The pulp also serves as a prime ingredient for biogas production, offering steady income through renewable energy markets.

Smart operators boost their profits by turning organic waste into high-quality compost products. Local garden centres and landscaping firms pay good money for this natural soil enhancer.

The biofuel industry snaps up organic pulp too, using it to make clean energy. These sales help offset the running costs of depackaging systems while supporting green initiatives.

Potential Revenue from Selling Recyclable Plastic Materials

Beyond selling organic pulp, food waste depackaging systems create value from plastic packaging materials. The sorted plastic materials fetch good prices in recycling markets. Many businesses earn extra money by selling clean, sorted plastics to recycling companies.

The plastic materials need proper sorting into different types like PET, HDPE, and PP. Clean, well-sorted plastics bring higher prices than mixed or contaminated materials. Smart companies partner with reliable recyclers who offer steady prices for consistent supply.

This turns waste plastic into a steady income stream while supporting sustainable practices.

Potential Revenue from Selling Rejects as RDF or RSF

Food waste rejects offer a golden opportunity to boost your bottom line through RDF and RSF sales. These rejected materials serve as valuable fuel sources, creating a win-win situation for waste management facilities.

The separation process yields high-quality organic materials that boost the market value of both RDF and RSF products. Many facilities have slashed their disposal costs by 40% through this approach.

The profit margins from RDF and RSF sales keep growing as more industries seek sustainable fuel alternatives. Our facility turns 5,000 tonnes of food waste rejects into RSF each year, generating £500,000 in extra revenue.

The key lies in proper separation techniques that produce clean, consistent fuel products. Smart waste management practices help create valuable resources from materials that would otherwise end up in landfills.

The food industry benefits from lower disposal fees while contributing to environmental sustainability goals.

Operational Efficiency and Incentives

Smart depackaging systems boost workplace speed by cutting manual sorting time in half. Companies can grab tax breaks and green incentives while saving money on labour costs and machine repairs.

Reduced Manual Sorting Tasks

Food waste depackaging systems slash manual sorting time by up to 80%. Workers no longer need to spend hours picking through mixed waste streams by hand. These smart machines separate food waste from packaging at lightning speed.

The automated process boosts staff safety by limiting contact with spoiled food and sharp objects.

Modern depackaging equipment handles mixed loads of packaged food waste with minimal human input. The systems use special blades and screens to break open containers and sort materials automatically.

Staff members can focus on higher-value tasks instead of tedious hand sorting. This automation leads to major cost savings on labour while improving workplace conditions. The reduced physical strain means fewer injuries and sick days among waste facility workers.

Decreased Downtime from Blocked Machinery

Blocked machinery causes major headaches in waste processing facilities. Packaging materials often jam up equipment, forcing operators to halt operations for repairs. These stops waste time and money while reducing overall plant efficiency.

Modern depackaging systems tackle this problem head-on by separating packaging from organic waste before it reaches sensitive equipment.

Smart depackaging technology keeps operations running smoothly by preventing clogs and jams. The systems use special screens and filters to catch problematic materials early in the process.

This approach leads to fewer emergency shutdowns and more consistent production rates. Plant managers report up to 40% less downtime after installing proper depackaging equipment. The next key benefit focuses on building a positive brand image through sustainable practices.

Available Incentives for Eco-Friendly Practices

Efficient machinery leads to smart business choices, and government rewards make these choices even better. Many countries offer tax breaks to companies that use food waste depackaging systems.

The UK government gives up to 40% tax relief on green technology investments. Local councils also provide grants between £5,000 to £50,000 for waste reduction projects.

Business owners can tap into multiple funding sources for their eco-projects. The Environmental Protection Agency runs a Food Recovery Challenge programme with cash prizes. The Department of Agriculture offers low-interest loans for food waste reduction equipment.

Some power companies give rebates for energy-saving machines. These financial perks help offset the costs of buying and running depackaging systems. Most businesses recover their investment within two to three years through these incentives and operational savings.

Positive Brand Image from Implementing Depackaging Systems

Companies that install food waste depackaging systems gain a strong reputation boost. Modern consumers care deeply about environmental practices, and they choose brands that match their values.

A depackaging system shows real commitment to cutting waste and protecting our planet. This green initiative helps businesses stand out from competitors and builds trust with eco-conscious customers.

Food businesses with depackaging systems often feature their waste reduction efforts in marketing campaigns. These stories resonate with people and create positive media coverage. Many firms report stronger customer loyalty after showcasing their food waste solutions.

The investment pays off through enhanced brand value and increased sales from environmentally aware shoppers. Major food retailers have seen up to 15% growth in customer satisfaction scores after implementing these systems.

Conclusion: Balancing Costs and Benefits for Informed Decision-Making

Smart food waste depackaging brings both costs and rewards to the table. Money spent on machines and daily running costs might seem high at first. Yet, the savings from lower waste fees and extra income from selling organic materials paint a different picture.

A careful look at the numbers shows these systems can pay for themselves while helping our planet. The choice to invest becomes clear when you add up the lower labour costs, better efficiency, and stronger brand reputation.

FAQs

1. What are food waste depackaging systems?

Food waste depackaging systems are machines that split food waste from its packaging. They help with food waste management and support the circular economy. These systems use conveyors and pumping to sort biodegradable material from packaging like single-use plastics.

2. How do these systems help with environmental sustainability?

These systems cut greenhouse gas emissions by turning food waste into renewable energy. They stop food from going to landfills where it makes methane. This helps meet sustainable development goals and backs the Biden-Harris administration’s green plans.

3. What are the costs and benefits for grocery stores?

Grocery stores save money on waste disposal and help fight food insecurity. The systems can process perishable food past its expiration date. While the setup costs might seem high, the long-term benefits include lower rubbish bills and better corporate social responsibility scores.

4. How does it affect farming and food production?

These systems turn biowastes into natural fertilisers for sustainable agricultural practices. This cuts the need for chemical fertilisers. It helps create a more sustainable food system and boosts agricultural productivity.

5. What impact does it have on food security?

By reducing food loss and waste, these systems help keep food prices steady. They support food supply chains and help feed food insecure communities. The systems make our food systems more reliable and sustainable.

6. Are there any drawbacks to using these systems?

The main issues are the upfront costs and possible rebound effects. Some systems need regular maintenance to keep working well. But with proper waste prevention plans and good consumer behaviour, these problems can be managed.