Depackaging Machines: Ultimate Guide to Food & Organic Waste Separation Equipment (2025)

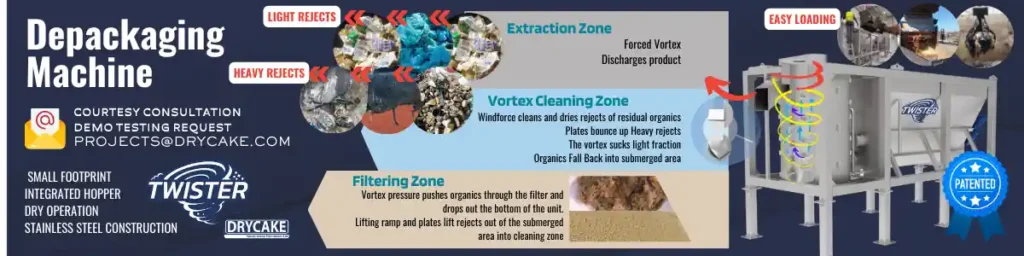

Discover how industrial depackaging machines streamline organic waste processing in 2025. Compare top separation technologies, ROI benefits, and solutions for food waste recycling and biogas production. An Introduction to Depackaging Machines Did you know that over 30% of food waste arrives at processing facilities still in its packaging? That’s why depackaging equipment has become a…