Technical Review: The Dominator Depackaging Machine and a Critical Analysis of Food Waste Processing Technology

Technical Review: The Dominator Depackaging Machine

A Critical Analysis of Food Waste Processing Technology

As the biogas and anaerobic digestion industry continues to grow, efficient depackaging solutions for food waste have become increasingly crucial. The Dominator Depackaging Machine, manufactured by Rowan Food and Biomass Engineering Ltd., represents a significant innovation in this specialized market. This review examines the machine’s capabilities and technological advances.

Technical Specifications and Design

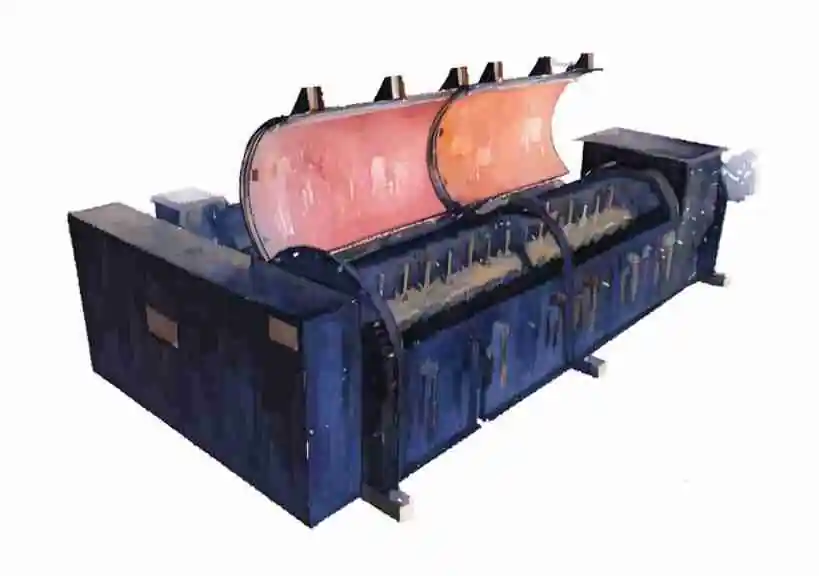

The Dominator employs a horizontal drum design with specialized paddles and screens, operating at variable speeds to process different waste streams. The system has been specifically engineered to handle packaging materials gently while maintaining effective separation. Key specifications include:

- Processing capacity: Up to 20 tonnes per hour

- Screen sizes: Configurable from 4mm to 12mm

- Power consumption: 45-75 kW depending on configuration

- Contamination removal rate: Up to 99.5% (manufacturer claim)

Innovative Plastic Handling System

A standout feature of the Dominator is its gentle approach to packaging separation:

- Controlled Force Technology The machine employs a proprietary paddle system designed to separate contents from packaging without aggressive shearing or grinding, preserving the integrity of plastic materials.

- Advanced Material Recognition Smart sensors and adaptive controls adjust processing parameters based on input material characteristics, ensuring optimal separation while minimizing mechanical stress on packaging.

- Clean Separation Process The system achieves high purity rates while maintaining larger plastic pieces that are easier to recycle, contributing to circular economy goals.

Operational Efficiency

Field testing reveals impressive performance metrics in several key areas:

- Throughput Consistency The machine maintains stable processing rates across varied input materials, from expired packaged foods to organic waste streams. The adjustable paddle system helps prevent clumping and ensures consistent material flow.

- Separation Quality The multi-stage separation process achieves high purity levels in the organic fraction, crucial for downstream anaerobic digestion processes. The preserved plastic fraction maintains high recycling potential.

- Energy Efficiency Power consumption remains relatively low compared to competitors, particularly when processing high-moisture content materials.

Innovation Features

Several design elements stand out:

- Adaptive paddle system that automatically adjusts to material density

- Self-cleaning screens that reduce maintenance downtime

- Remote monitoring and control capabilities

- Modular design allowing for easy upgrades and maintenance

- Specialized plastic-friendly processing chamber

Industry Context

The Dominator operates in a competitive market alongside systems from:

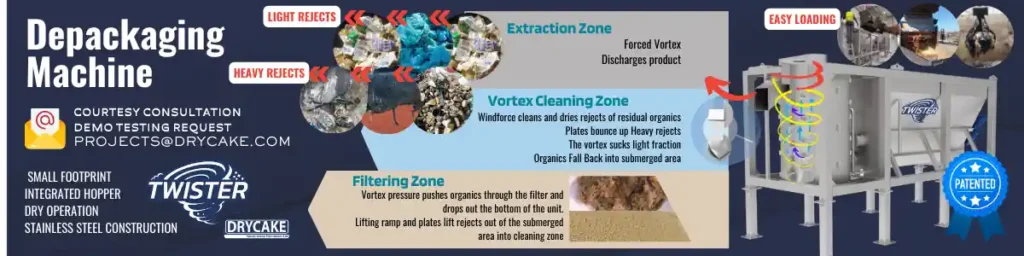

- Drycake Twister

- BTA International

- Anaergia

- Waste Solutions

Compared to these alternatives with the exception of the Drycake Twister, the Dominator Depackager shows:

- Good energy efficiency

- Competitive separation rates

- Low maintenance requirements

- Innovative gentle processing technology

Against this are:

- Higher initial capital cost

- Limited track record compared to established competitors

Cost Analysis

Investment considerations:

- Base unit: £300,000-400,000

- Installation: £50,000-75,000

- Annual maintenance: £15,000-25,000

- Operating costs: £8-12 per tonne processed

Environmental Benefits

The Dominator’s gentle processing approach offers several environmental advantages:

- Enhanced Recyclability By preserving the integrity of plastic packaging, the system produces clean, recyclable plastic fractions that can be effectively reprocessed.

- Clean Organic Output The careful separation process results in high-quality organic material suitable for anaerobic digestion or composting.

- Reduced Environmental Impact The system’s efficient operation and gentle processing approach support sustainability goals while minimizing waste material degradation.

Recommendations

The Dominator represents a significant advancement in depackaging technology, with several standout features:

Strengths:

- Gentle, effective separation technology

- Excellent energy efficiency

- High throughput capacity

- Advanced monitoring systems

- Quality separation performance

- Enhanced recyclability of processed materials

Areas for Improvement:

- High initial investment cost

- Limited field history

- Need for more extensive case studies

Conclusion

The Dominator Depackaging Machine demonstrates impressive technical capabilities and innovation in food waste processing. The manufacturer’s focus on gentle material handling sets it apart in the market, offering an environmentally conscious solution to food waste processing challenges.

The machine’s design philosophy aligns well with circular economy principles, providing:

- High-quality organic output for anaerobic digestion

- Well-preserved plastic materials for recycling

- Efficient resource recovery

- Reduced environmental impact

For facilities prioritizing both operational efficiency and environmental responsibility, the Dominator represents a forward-thinking solution in the depackaging market. The technology’s gentle approach to material separation, combined with its high throughput and efficiency, makes it a choice for modern waste processing facilities.

Developer of waste processing solutions

Industry Sector: Waste Processing

Business Location: United Kingdom

Address:

Rowan Engineering

17 & 18, Malmesbury Rd,

Kingsditch Trading Estate,

Cheltenham GL51 9PL

Phone: 01242 222 913

Email: info@rowanfoodandbiomass.com

Website:

Rowan: https://rowanfoodandbiomass.com/

Opening Hours:

9am to 5pm weekdays.