Dycake Twister Depackaging Machine: Revolutionary Food Waste Separation Technology 2024

Did you know that approximately 40% of food waste ends up in landfills still in its packaging? That’s where the Dycake Twister Depackaging and Separation Machine comes in! This revolutionary piece of equipment is transforming how businesses handle packaged food waste separation. I’ve seen firsthand how this innovative technology is helping companies achieve up to 99% separation efficiency while significantly reducing their environmental impact. Let’s dive into everything you need to know about this game-changing machine!

What is the Dycake Twister Depackaging Machine?

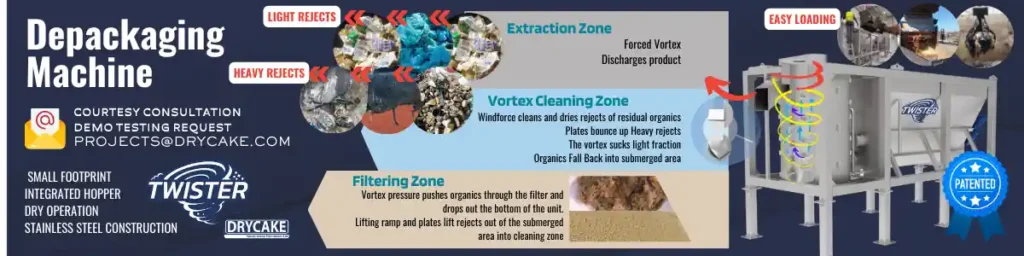

The Dycake Twister represents the pinnacle of waste separation technology, specifically designed to tackle one of the most challenging aspects of waste management: separating food waste from its packaging. This robust machine utilizes advanced centrifugal force technology combined with precision-engineered separation mechanisms to effectively process various types of packaged waste.

Key specifications include:

- Processing capacity: Up to 15 tons per hour

- Separation efficiency: 99%+

- Compact footprint: 25′ x 12′ standard unit size

- Advanced control system with touchscreen interface

- Stainless steel construction for durability and hygiene

The machine excels at processing a wide range of packaging materials, including:

- Plastic containers and bottles

- Cardboard and paper packaging

- Metal cans and containers

- Glass bottles and jars

- Multi-layer packaging materials

Features and Benefits of the Dycake Twister

The Dycake Twister stands out in the market thanks to its innovative features that deliver exceptional performance and reliability.

Advanced Separation Technology

Our proprietary separation system uses a combination of mechanical forces and intelligent sorting algorithms to achieve optimal separation results. The machine’s unique twisting action ensures thorough separation while minimizing damage to both organic material and packaging components.

Automated Operation

The fully automated system requires minimal operator intervention, featuring:

- Continuous feed capability

- Real-time monitoring and adjustments

- Automated cleaning cycles

- Remote operation capabilities

- Intelligent load sensing

Energy Efficiency

The Dycake Twister is designed with sustainability in mind:

- Energy-efficient motors and drives

- Smart power management system

- Heat recovery options

- Low water consumption

- Optimized processing cycles

Applications Across Different Industries

The versatility of the Dycake Twister makes it invaluable across multiple sectors:

Food Manufacturing

- Processing expired products

- Handling production line waste

- Separating rejected products

- Managing recall materials

- Processing raw material waste

Retail and Supermarkets

- Efficient handling of expired goods

- Processing damaged packages

- Managing recalled products

- Separating organic waste

- Handling mixed waste streams

Beverage Industry

- Processing expired beverages

- Handling production rejects

- Managing recalled products

- Separating packaging materials

- Processing liquid waste

Installation and Integration Process

Getting your Dycake Twister up and running is a streamlined process:

- Site Assessment

- Facility evaluation

- Space requirements review

- Utility assessment

- Integration planning

- Safety considerations

- Installation

- Professional installation team

- Minimal disruption to operations

- Comprehensive testing

- System calibration

- Performance verification

- Training and Support

- Operator training programs

- Maintenance staff education

- Safety protocol training

- Troubleshooting guidance

- Ongoing support

Return on Investment Analysis

Investing in a Dycake Twister delivers significant financial benefits:

Cost Savings

- Reduced labor costs (up to 75% reduction in sorting personnel)

- Lower waste disposal fees

- Decreased transportation costs

- Improved material recovery value

- Reduced environmental compliance costs

Environmental Benefits

- Reduced landfill waste

- Increased recycling rates

- Lower carbon footprint

- Improved sustainability metrics

- Enhanced corporate environmental responsibility

Maintenance and Support

Keeping your Dycake Twister running at peak performance is straightforward:

Regular Maintenance

- Daily cleaning procedures

- Weekly inspection routines

- Monthly preventive maintenance

- Quarterly major service

- Annual comprehensive overhaul

Support Services

- 24/7 technical support

- Remote diagnostics

- Rapid response service teams

- Comprehensive warranty coverage

- Spare parts inventory management

Conclusion

The Dycake Twister Depackaging and Separation Machine represents a significant leap forward in food waste management technology. With its impressive separation efficiency and robust design, it’s helping businesses across industries streamline their waste management processes while contributing to sustainability goals. Ready to revolutionize your waste management system? Contact a Dycake representative today to learn how this innovative solution can benefit your operation!

Don’t let packaged waste continue to burden your operations and the environment. Join the growing number of forward-thinking companies that have already discovered the power of the Dycake Twister. Your journey toward more efficient, sustainable waste management starts here!

Contact us today for a personalized consultation and demonstration of the Dycake Twister in action.

Manufacturer of separation equipment

Industry Sector: Separation Technology

Business Location: HQ in Quebec Canada & Belgium

Description:

Drycake Twister is a company specializing in de-packaging and separating organic waste from inorganic materials.

Their flagship product, the Twister De-packager & Separator, efficiently separates packaging from food or other organic matter, making it suitable for composting or anaerobic digestion. This process is crucial for optimizing waste management and reducing environmental impact.

Address:

Drycake BV

Koningslinde 26e

7131MP Lichtenvoorde

The Netherlands

Contact: Mark Vanderbeken

e-mail: europe@drycake.com

Phone: +31 544 79 23 00

Website:

Twister Separator: www.twisterseparator.com

Opening Hours:

Monday to Friday 9 am to 5 pm