In recent years, recycling facilities have increasingly recognized the importance of efficient food waste depackaging systems. A good system can efficiently separate organic material from its packaging, ensuring that each can be disposed of in the most environmentally friendly way possible. However, with a plethora of systems available on the market, making an informed decision can be a daunting task. This article provides a comprehensive guide to assist recycling facilities in selecting the most appropriate food waste depackaging system.

The first step towards selecting the best food waste depackaging system is understanding your facility’s specific needs and requirements. The quantity and type of waste processed daily, desired throughput rate, space availability, and budget restrictions are critical factors to consider.

- Quantity and Type of Waste: The volume and kind of waste your facility handles will significantly influence your choice. For example, if you process high volumes of packaged food waste, you may require an industrial-grade system with high capacity for optimal efficiency.

- Throughput Rate: This refers to the amount of waste that a machine can process within a specified duration – typically measured per hour or per day. If your facility processes large amounts of food waste regularly, you should opt for a machine with a high throughput rate.

- Space Availability: Space is often at a premium in many recycling facilities. Therefore, it’s crucial to choose a machine that fits well within your available space without compromising its functionality or workflow efficiency.

- Budget: Like any other investment decision, cost plays an integral role in choosing a depackaging system. However, it’s important not to compromise on quality or suitability for lower prices.

Once these factors are clear, delve into specific features and capabilities that make certain systems stand out:

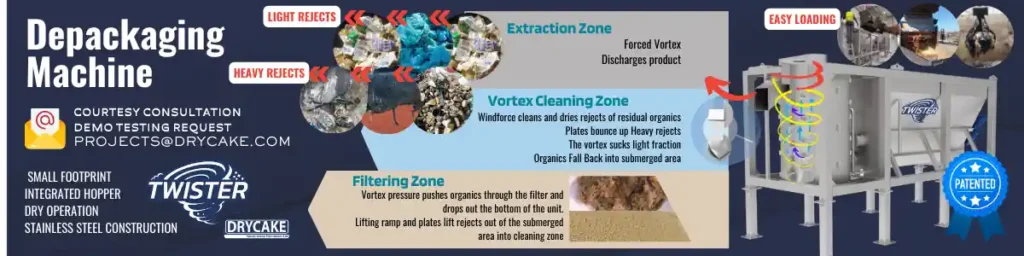

Efficiency: An efficient depackaging system will separate organic material from its packaging quickly and effectively without causing jams or slowdowns.

Versatility: The best systems can handle multiple types of waste beyond just food, such as pet food, drinks, and personal care products. This flexibility allows for the processing of a broader range of materials.

Durability: A robust system with high-quality components will endure the rigors of heavy usage and last longer, reducing maintenance costs and downtime.

Ease of Use: The system should be easy to operate, reducing the need for extensive training. Furthermore, it should be easy to clean and maintain to ensure long-term performance.

Environmental Impact: Consider the machine’s water usage and energy efficiency. A system that uses less water and energy will not only save on utility bills but also minimize your facility’s environmental footprint.

Lastly, consider the reputation of the manufacturer and after-sales support. A reputable manufacturer is likely to produce high-quality machines that are reliable and effective. They should also offer excellent after-sales service, including maintenance support and spare parts availability.

In conclusion, choosing the best food waste depackaging system involves careful consideration of various factors ranging from your facility’s specific needs to budget constraints. By evaluating these factors carefully and prioritizing efficiency, versatility, durability, ease of use, environmental impact, manufacturer reputation, and after-sales support – you can ensure you make an informed decision that enhances your recycling facility’s operations while minimizing its environmental impact.