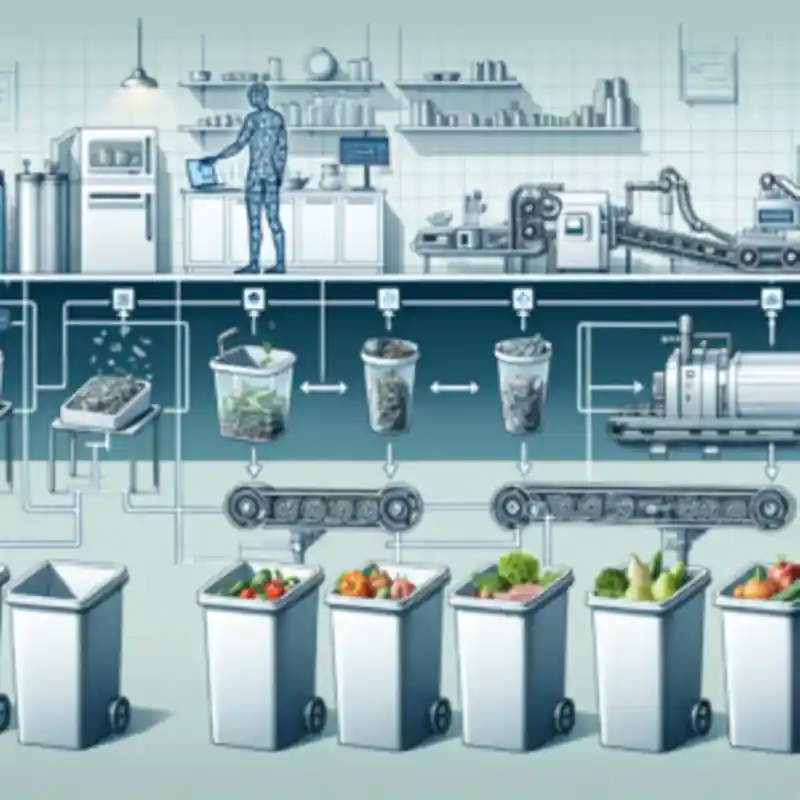

High-tech solutions are transforming how we handle food waste, with new depackaging systems leading the charge in sustainable processing.

Did you know that a staggering 1.3 billion tons of food is wasted globally each year? But here’s the exciting part – innovative technologies are changing the game! I’ve spent months researching the latest developments in food waste separation, and I’m amazed by how far we’ve come. From AI-powered sorting systems that can identify and separate food waste with 99% accuracy to sophisticated depackaging systems that minimize microplastic generation, we’re witnessing a technological revolution in waste management.

Artificial Intelligence and Machine Learning Solutions

The integration of AI into waste management has revolutionized how we identify and sort food waste:

- Deep learning algorithms now enable real-time waste identification with unprecedented accuracy

- Computer vision systems can automatically detect and categorize different types of packaging

- Neural networks help detect contamination before it affects the separation process

- AI-powered analytics provide detailed reporting on waste composition and processing efficiency

- Predictive maintenance systems help prevent costly equipment downtime

Advanced Depackaging Technologies for Food Waste Separation

Let’s dive into three leading depackaging technologies that are transforming the industry:

Drycake Twister Depackager

The Drycake Twister Depackager represents a significant advancement in food waste separation technology. Here’s what makes it special:

- Uses a unique horizontal paddle system that creates less friction during separation

- Generates notably lower levels of microplastics compared to traditional systems

- Achieves separation rates of up to 99% for most packaging types

- Features adjustable processing parameters for different packaging materials

- Includes a self-cleaning mechanism that reduces maintenance requirements

Mavitec Depackaging Technology

Mavitec’s system offers some distinct advantages:

- Employs a vertical grinding process with specialized cutting tools

- Produces medium levels of microplastics due to its grinding mechanism

- Handles a wide variety of packaging materials including glass and metal

- Features high throughput capacity for industrial-scale operations

- Includes built-in foreign object detection and removal

Flexidry Depackager Technology

The Flexidry system brings its own unique approach:

- Utilizes a gentle paddle system designed to minimize packaging destruction

- Generates the lowest levels of microplastics among the three systems

- Achieves excellent separation results with delicate packaging

- Features precise control over processing speed and intensity

- Includes advanced moisture control systems for optimal output quality

Microplastic Generation Comparison

When it comes to microplastic generation, here’s how these technologies stack up:

- Flexidry Depackager

- Lowest microplastic generation

- Typically produces <50 particles per kg of processed material

- Ideal for operations prioritizing environmental impact

- Drycake Twister

- Moderate to low microplastic generation

- Produces approximately 100-150 particles per kg

- Good balance between efficiency and environmental impact

- Mavitec System

- Moderate microplastic generation

- Produces approximately 200-250 particles per kg

- Higher throughput comes with increased microplastic production

Smart Bin Technologies and IoT Integration

Beyond depackaging, modern waste management systems incorporate smart technologies:

- Connected waste bins with weight sensors improve collection efficiency

- Real-time fill level monitoring prevents overflow issues

- Automated lid systems reduce contamination

- Mobile app integration enables better tracking and reporting

- Cloud-based platforms provide comprehensive waste management solutions

Optical Sorting Systems

Advanced optical systems complement depackaging technologies:

- Near-infrared (NIR) spectroscopy ensures accurate material identification

- High-speed cameras capture and process thousands of images per second

- Color detection technology helps identify different packaging types

- Material composition analysis ensures proper separation

- Multi-sensor fusion systems provide redundancy and improved accuracy

Biological and Chemical Separation Methods

These methods often work in conjunction with mechanical separation:

- Enzymatic processes break down organic materials

- Membrane filtration systems remove contaminants

- Density-based separation improves material recovery

- Molecular sorting technology targets specific compounds

- Biochemical treatments prepare materials for further processing

Future Trends and Developments

The food waste separation technology sector continues to evolve:

- Integration of blockchain for improved traceability

- Development of more sophisticated AI algorithms

- Increased focus on microplastic reduction

- Enhanced automation and remote monitoring capabilities

- Greater emphasis on energy efficiency

Conclusion – Food Waste Separation

The landscape of food waste separation technology is more exciting than ever! While each system has its strengths, the Flexidry Depackager currently leads in minimizing microplastic generation, making it an excellent choice for environmentally conscious operations. The Drycake Twister offers a strong balance between performance and environmental impact, while the Mavitec system excels in high-throughput applications.

When choosing a system, consider your specific needs: Do you prioritize throughput, environmental impact, or versatility? Many facilities are now opting for hybrid solutions that combine different technologies to achieve optimal results.

Ready to take your waste management to the next level? Start by evaluating which of these cutting-edge technologies aligns best with your specific needs and goals. The future of sustainable waste management is here – it’s time to embrace it!

These innovative technologies are paving the way toward more sustainable practices in handling food waste. By offering more efficient ways to separate food waste from other types of trash, they not only help reduce landfill volumes but also turn what was once considered ‘waste’ into valuable resources such as energy or soil enhancers. The future of food waste management indeed looks brighter with these technological advancements at our disposal.