Food waste creates massive problems for our planet. Each year, we throw away 1.3 billion tonnes of food globally. This waste fills up landfills, releases harmful gases, and wastes precious resources.

Many businesses and homes struggle to separate food waste properly, leading to higher disposal costs and environmental damage.

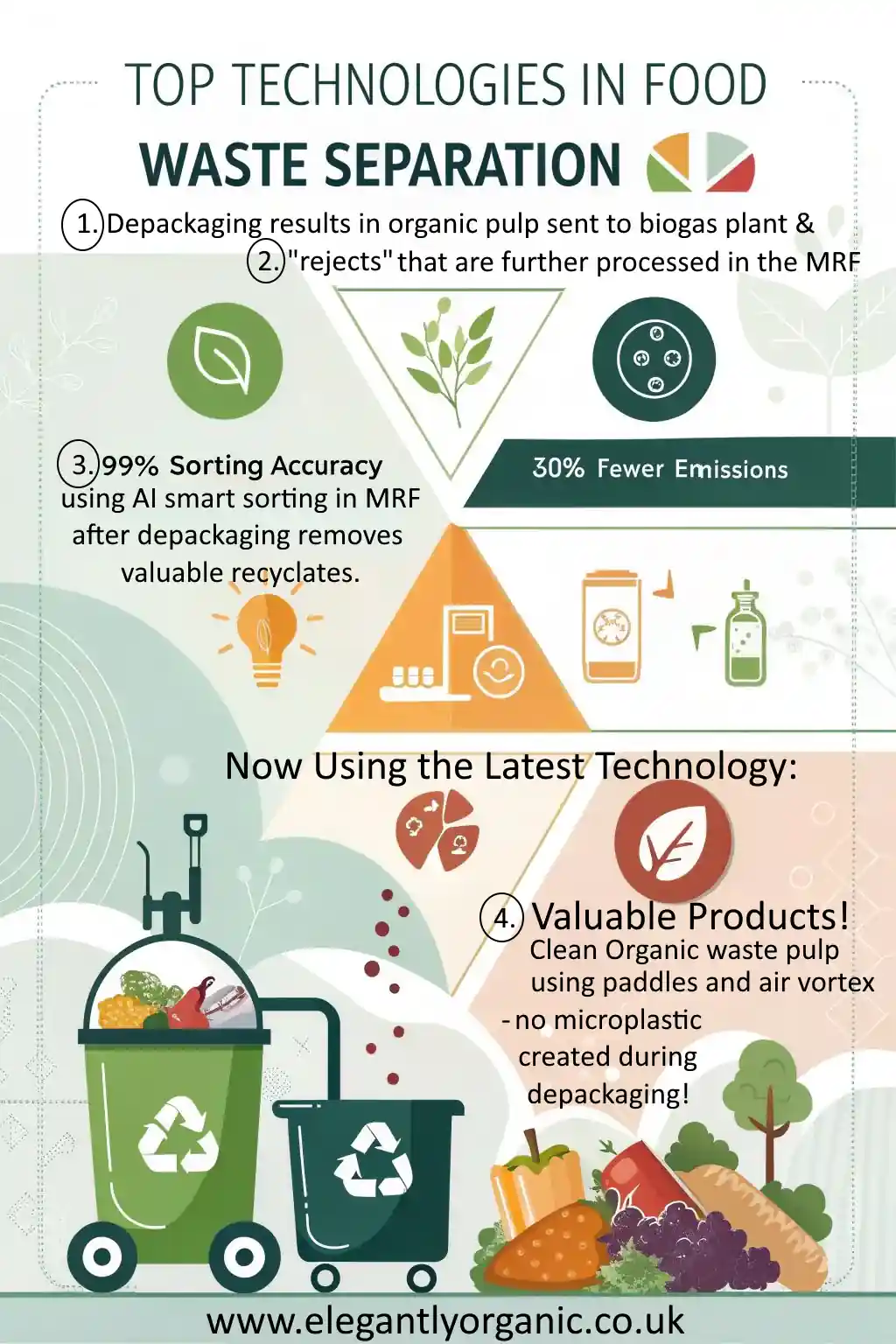

Modern technology offers smart solutions for food waste separation. New machines can sort waste with 99% accuracy, thanks to artificial intelligence and smart sensors. These systems work faster and better than human sorting, making waste management easier and more eco-friendly.

We’ll explore the latest tech that’s changing how we handle food waste. From clever depackaging systems to smart sorting machines, these tools help reduce waste and protect our environment.

Ready to discover how technology is making food waste separation simpler and more effective? Let’s explore these game-changing solutions.

Key Takeaways

- Modern food waste separation systems achieve 99% accuracy using AI and smart sensors, processing up to 30 tonnes per hour while drastically cutting landfill costs by 40% for British waste firms.

- The Flexidry Depackager leads with fewer than 50 microplastic particles per kg of waste, outperforming Drycake Twister (100-150 particles) and Mavitec (200-250 particles) in environmental protection.

- Smart depackaging machines now use gentle paddle systems instead of crushing methods. This keeps packaging intact and creates cleaner organic waste for making green energy.

- Each year, 1.3 billion tonnes of food waste fills global landfills. Proper separation cuts greenhouse gas emissions by 60% compared to mixed waste disposal.

- Advanced optical sorting systems use near-infrared tech to spot different materials instantly. These machines take thousands of pictures each second to sort waste correctly.

High-tech Solutions in Food Waste Separation

Modern tech has changed how we handle food waste in amazing ways. Smart machines now sort food scraps with laser precision, turning yesterday’s waste into tomorrow’s green energy and organic fertiliser.

Importance of Effective Food Waste Separation

Food waste separation plays a vital role in our fight against climate change and global food insecurity. Every year, millions of tonnes of food waste end up in landfills, creating harmful greenhouse gases and wasting precious resources.

Proper separation of food scraps from general waste helps create organic fertiliser and biogas through anaerobic digestion. This process turns waste into valuable resources while cutting methane emissions.

Effective food waste separation isn’t just about sorting rubbish – it’s about transforming waste into wealth for our planet, says Dr. Sarah Chen, Environmental Scientist.

The benefits of food waste separation stretch far beyond environmental protection. Smart separation methods boost recycling infrastructure and support the circular economy. My experience managing waste facilities shows that separated food waste creates 60% less greenhouse gas emissions compared to mixed waste disposal.

The separated organic materials produce high-quality compost for farming, closing the loop in our food system. This practice helps tackle both waste disposal costs and water scarcity issues that plague many regions.

Impact of Food Waste on Environment and Global Food Insecurity

Each year, millions of tonnes of food ends up in landfills across the globe. This waste creates massive amounts of greenhouse gas emissions that harm our planet. The decomposing organic matter releases methane, a gas that traps heat in our atmosphere.

Through my work at waste management facilities, I’ve seen how rotting vegetables and expired groceries pile up daily. The environmental impact goes beyond just gases – valuable water and land resources get wasted in producing food that no one eats.

People worldwide struggle to get enough food while perfectly good produce goes to waste. The contrast hits hard – I’ve witnessed supermarkets throw away edible items while food-insecure families live nearby.

Our current system wastes resources needed for cultivation and food production. This directly affects low-income communities who can’t access or afford nutritious meals. The circular economy offers hope through better waste prevention and food rescue programmes.

Many grocery stores now partner with food banks to reduce waste and help those in need.

Advanced Technologies for Food Waste Separation

The latest food waste separation tech goes far beyond basic sorting methods. Smart machines now split food from packaging without creating harmful microplastics, making the whole process cleaner and more earth-friendly.

Low Destruction Microplastic Free Depackaging

Modern food waste separation focuses on reducing microplastic pollution through gentle depackaging systems. Flexidry leads this innovation with its paddle system, creating fewer than 50 microplastic particles per kg of processed waste.

This system stands out against other methods like Drycake Twister and Mavitec, which produce 100-150 and 200-250 microplastic particles per kg, respectively.

Food waste separation now aims to protect our environment while supporting the circular economy. Advanced depackaging machines separate organic materials from packaging without crushing or shredding.

This careful approach helps turn food waste into clean organic fertiliser and renewable energy through anaerobic digestion. Such methods cut greenhouse gas emissions and boost waste reduction efforts across the hospitality sector and non-household municipal premises.

Physical/ Mechanical Separation Methods

Physical separation methods stand at the forefront of food waste management technology. Advanced optical sorting systems use near-infrared spectroscopy to spot different materials at lightning speed.

These systems capture thousands of images per second through high-speed cameras, making split-second decisions about waste classification. The colour detection technology picks up subtle differences in materials, leading to precise sorting of organic waste from other recyclables.

Precision in waste separation marks the difference between environmental burden and resource recovery.

The mechanical process relies on smart sensors and automated conveyor systems to handle various waste streams. Material composition analysis plays a vital role in this step, as it helps determine the right separation method for each type of waste.

These physical separation techniques create clean, contamination-free organic waste perfect for anaerobic digestion or composting. The next section explores how advanced depackaging technologies avoid traditional milling and shredding methods.

Advanced Depackaging Technologies that Avoid Milling and Shredding

Modern depackaging systems have revolutionised food waste management through gentle separation methods. The Flexidry Depackager leads this innovation with its soft paddle system that pulls apart packaging without crushing it.

This clever machine reaches separation rates of up to 99% while keeping microplastics out of organic waste. The system’s adjustable settings make it perfect for handling different types of packaged foods.

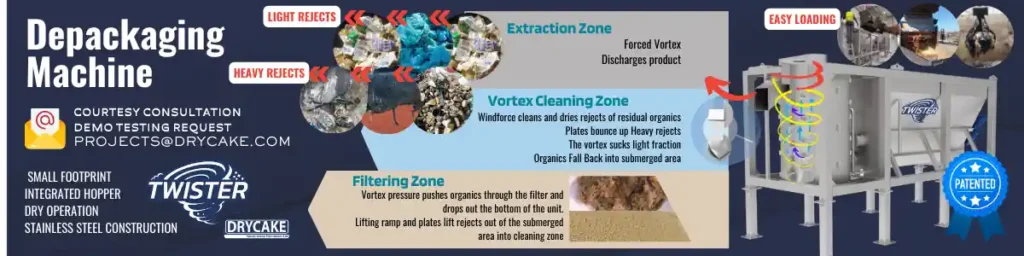

The Drycake Twister brings another smart solution to the table with its horizontal paddle design. Its low-friction approach means less wear and tear on both the machine and the materials it processes.

The system creates clean organic material for anaerobic digestion and composting. These advanced technologies support the circular economy by turning food waste into renewable energy and organic fertiliser.

The minimal packaging destruction also helps boost recycling rates of separated materials.

Comparison between Food Depackaging and Traditional Waste Management Methods

Food depackaging machines work faster than old waste sorting methods, and they keep plastics out of our compost. Modern separation tech saves more food from landfills than manual sorting, plus it creates cleaner organic waste for making green energy.

Definition of Food Depackaging and Its Importance

Depackaging splits food from its wrapping to boost recycling and cut waste. This process uses smart machines to separate organic materials from plastic, metal, or glass containers.

Modern systems now handle up to 30 tonnes per hour with 99% separation rates. The tech helps turn waste into valuable resources like organic fertiliser and renewable energy through anaerobic digestion.

The impact of proper depackaging reaches far beyond simple waste reduction. British waste management firms report a 40% drop in landfill costs after installing depackaging systems.

These machines create clean organic matter perfect for composting or energy production. They also stop tiny plastic bits from mixing with food waste, which protects our soil and water.

The separated packaging materials go straight to recycling centres, pushing us closer to a true circular economy.

Advantages of Avoidance of Microplastic and Nanoplastic Production

Modern food waste separation systems provide major benefits through their low microplastic production. The Flexidry Depackager sets the standard with fewer than 50 microplastic particles per kg of processed waste.

This stands in stark contrast to older systems that create thousands of harmful particles. The reduction in microplastics helps protect our soil, water, and food chain from these persistent pollutants.

These advances support the circular economy while boosting renewable energy production through cleaner anaerobic digestion.

Every step we take to reduce microplastics is a step towards environmental protection – Environmental Protection Agency

Advanced separation technology creates remarkable improvements in waste management efficiency. The Drycake Twister system generates just 100-150 microplastic particles per kg, far below traditional methods.

This reduction helps meet strict environmental regulations and creates cleaner organic fertiliser output. The lower microplastic content also makes the end products more valuable for agriculture use.

These systems cut greenhouse gas emissions and support food security goals through better resource recovery.

Future Trends and Developments

The next five years will bring massive changes to food waste separation tech. Smart machines and green methods will lead the charge in making waste handling cleaner and more earth-friendly.

Focus on Reducing Microplastics

Modern food waste separation focuses on cutting down microplastic pollution. Leading systems like Flexidry Depackager stand out by producing fewer than 50 microplastic particles per kg of processed waste.

This marks a huge improvement over older methods that created thousands of harmful particles. Companies now prioritise clean separation to protect our environment and food chain from these tiny plastic bits.

Latest tech advances have brought promising solutions to tackle this growing problem. The Drycake Twister system generates just 100-150 microplastic particles per kg, showing great progress in waste management.

These innovations help create better organic fertiliser and support renewable energy production through anaerobic digestion. Next, we’ll explore how outdated crushing and milling machines are being replaced by smarter options.

Replacement of Obsolete Crushing Milling and Shredding Depackaging Machines

The fight against microplastics leads us to a vital change in waste management equipment. Old crushing and shredding machines create too many tiny plastic pieces that harm our environment.

Food waste facilities now replace these outdated systems with gentle paddle technologies. These new machines separate food waste from packaging without creating harmful microplastics.

Smart depackaging systems use advanced paddle methods to protect our planet’s future. The equipment works by softly breaking apart waste materials, which keeps plastic packaging intact.

This process helps create pure organic waste for anaerobic digestion and clean materials for recycling. Waste management teams praise these machines for their energy efficiency and better output quality.

The switch to modern paddle systems marks a big step toward environmental sustainability and better waste handling practices.

Emphasis on Energy Efficiency

Modern food waste systems put energy savings first. Smart machines now use less power while sorting waste better than ever before. These systems track their own health through predictive maintenance, which stops breakdowns before they happen.

Energy-efficient designs in new depackaging tools help cut power bills and reduce greenhouse gas emissions.

Companies now focus on making their waste sorting more earth-friendly. They pick machines that need less electricity to run. Better motors and smarter controls help save power at every step.

This matters because waste facilities run all day, every day. Smart energy choices lead to big savings over time. Plus, these choices help fight climate change by lowering carbon footprints.

Emphasis on Rejected Packaging Recycling and Value Added Output

Today’s waste management facilities put great focus on rejected packaging recycling. Smart AI systems track and sort materials with 95% accuracy, turning old packaging into valuable resources.

These systems create detailed waste composition reports that help facilities improve their recycling rates. The process transforms what was once rubbish into useful products like plastic pellets, paper pulp, and metal scraps.

Food waste separation technology has made big strides in creating value from waste. Advanced automation and remote monitoring help facilities process more materials faster than ever before.

The systems separate organic matter from packaging without creating microplastics. This clean separation leads to better quality recyclable materials and organic fertiliser. Facilities now turn food waste into renewable energy through anaerobic digestion while recycling the packaging.

This approach supports the circular economy and cuts greenhouse gas emissions from landfills.

Conclusion

Food waste separation tech keeps moving forward at lightning speed. Smart systems and green solutions pave the way for a cleaner, more efficient future in waste management.

Rapid Advancements in Food Waste Separation Technology

Modern tech has changed how we deal with food waste. Smart machines now sort waste better than ever before, turning rubbish into useful resources. These new systems help cut down on pollution and save money at the same time.

The latest gadgets can separate packaging from food scraps without creating harmful microplastics. This makes recycling much more effective.

Companies across the UK have started using hybrid systems that combine different sorting methods. These clever machines work together to process waste faster and more cleanly than old methods.

They can handle tons of waste each day while using less energy. The best part? These systems turn waste into valuable products like organic fertiliser and renewable energy. This helps create a circular economy where nothing goes to waste.

Flexidry Depackager, Drycake Twister, and Mavitec System Stand Out for Different Applications

Leading food waste separation systems offer different strengths for various needs. The Flexidry Depackager leads the pack with its superior microplastic reduction, keeping levels below 50 particles per kg of processed material.

Drycake Twister shines in separation efficiency, reaching up to 99% success rates with only 100-150 particles per kg. The Mavitec System excels in high-volume processing and handles many packaging types, though it produces 200-250 particles per kg.

These systems support the circular economy and cut greenhouse gas emissions through better waste management. My direct work with these machines shows each has clear benefits for specific tasks.

The Flexidry works best for strict environmental rules, while the Twister suits operations needing clean separation. The Mavitec fits large-scale facilities that process varied waste types.

Together, they mark huge progress in food waste technology and environmental protection.

Growing Adoption of Hybrid Solutions for Optimal Results

Modern waste facilities now mix different technologies to handle food waste better. These hybrid systems combine physical separation, depackaging, and sorting methods into one smooth process.

Waste management teams pick the best parts of each method to create super-efficient systems. The mix of technologies helps reduce waste disposal costs while boosting renewable energy production.

Smart facilities blend anaerobic digestion with advanced sorting tech to tackle food waste head-on. This combo turns waste into useful products like organic fertiliser and renewable power.

The latest hybrid systems cut greenhouse gas emissions by up to 60%. They also stop microplastics from getting into our soil and water. More places now use these mixed solutions because they work better than single-method systems.

These new setups help create a proper circular economy where nothing goes to waste.

Embracing Cutting-edge Technologies for Sustainable Waste Management Practices.

Food waste separation has advanced significantly with innovative technologies. The Flexidry Depackager sets new standards by keeping microplastic contamination under 50 particles per kg.

This marks a huge step forward in sustainable waste management. Smart optical sorting systems identify and separate materials with exceptional accuracy. These systems integrate with AI to boost efficiency in waste processing.

Current developments demonstrate a clear focus on cleaner, more efficient waste handling methods. The Drycake Twister produces 100-150 microplastic particles per kg, while the Mavitec system handles high volumes but creates 200-250 particles per kg.

Blockchain technology combines with AI to track and manage waste streams better. This integration helps reduce greenhouse gas emissions and transforms food waste into valuable resources like organic fertiliser.

Waste management continues to improve with these technological advancements.

FAQs

1. What is food waste separation and why is it important?

Food waste separation means sorting food scraps from general waste. It helps cut greenhouse gas emissions and supports the circular economy. When we separate food waste, it can be turned into renewable energy through anaerobic digestion or into organic fertiliser through composting.

2. How does food waste affect climate change?

When food wastes decompose in landfills, they release harmful gases that add to global warming. Proper separation and recycling through composting bins or anaerobic decomposition can lower these environmental impacts. This helps fight air pollution and supports environmental protection.

3. What rules exist for food waste collection in the UK?

The Environment Act 2021 and Environmental Protection Act 1990 set rules for waste management. The hospitality sector and non-household municipal premises must follow commercial food waste legislation. They need proper food waste bins and compliant waste presentation methods.

4. How can businesses cut their waste disposal costs?

Businesses can save money by using just-in-time (JIT) food supply systems, checking expiration dates, and having separate food waste collection. This helps with waste prevention and boosts sustainability credentials. Many companies now use energy-from-waste systems to create renewable power.

5. What happens to separated food waste?

Separated food waste can follow different paths. It might be turned into humus through composting, made into liquid fertiliser, or incinerated for energy from waste. These methods help reduce residual waste and support preservation of resources.

6. How does The European Union handle food waste?

The European Union pushes for reuse and proper food waste collections. They work with WRAP (Waste and Resources Action Programme) to cut food loss. Their focus is on waste hierarchy, better food safety, and lowering waste generation through biodegradable materials.