Waste recycling machinery encompasses a broad range of equipment, from basic compactors and balers for cardboard/plastic to advanced shredders, screens, sorters, and material handlers used to process diverse waste streams like green waste, e-waste, and construction debris, helping businesses reduce costs and extract value by transforming waste into usable materials. Key types include Shredders (slow/high-speed), Balers & Compactors, Screens & Trommels, Sorting Systems, and Chippers, with options for hire, purchase, or bespoke solutions.

Key Takeaways

- Effective pre-treatment of solid waste using the right waste recycling machinery can increase resource recovery rates by up to 30% compared to landfilling untreated waste

- Modern shredders can process between 5-100 tons of municipal solid waste per hour depending on design and capacity

- Proper waste pre-treatment equipment selection can reduce disposal costs by up to 60% through volume reduction and material recovery

- The global waste pre-treatment equipment market is expected to grow at a CAGR of 4.8% through 2028

- Combining multiple pre-treatment technologies (like shredding and screening) can improve downstream processing efficiency by 25-40%

The mountains of waste we generate daily don’t just disappear on their own. Before waste can be recycled, converted to energy, or even properly landfilled, it needs to be processed through specialized equipment designed to transform mixed, irregular materials into manageable, uniform streams. This critical step is what we call pre-treatment.

Without pre-treatment equipment, modern recycling and waste-to-energy facilities wouldn’t be able to function efficiently or economically. These specialized machines are the backbone of any effective waste management system, turning our discarded materials from a chaotic mess into an organized system.

“Sutco: Pre Sorting before Power Plant …” from www.sutco.com and used with no modifications.

Quick Overview of Essential Equipment

There are many types of solid waste pre-treatment equipment, each with its own unique functions and benefits. These pieces of machinery use mechanical, biological, and physical processes to transform raw waste into a more manageable form. This makes it easier to handle, transport, sort, and process the waste. For those who work in waste management or operate waste facilities, it’s important to understand how these different technologies work. This knowledge can help you design more efficient systems that are better for the environment and more effective at recovering resources.

Choosing the right equipment is largely dependent on the type of waste, treatment objectives, space limitations of the facility, and budget constraints. Whether it’s a large-scale industrial shredder capable of processing several tons per hour, or a specialized sorter that uses optical technology to identify certain types of plastics, each piece of equipment has a unique role in the waste management process.

The Importance of Solid Waste Pre-treatment in Today’s Waste Management

“municipal solid waste …” from link.springer.com and used with no modifications.

There are several reasons why pre-treatment is a vital part of waste management. Firstly, it reduces the volume of waste, which significantly cuts down on transportation costs and increases the lifespan of landfills. When waste is shredded, compacted, or baled, it becomes much denser, which allows it to move through the waste handling system more efficiently. Secondly, pre-treatment makes waste streams more uniform, which creates a more consistent material that downstream processes can handle more efficiently. Thirdly, it makes it easier to separate materials, which leads to higher recovery rates of valuable recyclables like metals, plastics, and paper products.

There are also significant environmental benefits. Pre-treatment reduces the methane emissions from landfills by allowing for better compaction and potentially diverting organic material to composting or anaerobic digestion. It also increases the efficiency of waste-to-energy facilities by producing refuse-derived fuel (RDF) that burns more consistently. Perhaps most importantly, effective pre-treatment is what makes the principles of the circular economy practical in waste management by transforming “waste” into usable resource streams.

Waste Sizing Equipment: Preparing Waste for Efficient Processing

Waste sizing equipment is the first step in waste processing, physically breaking down large, bulky waste items into smaller, easier to handle pieces. This vital first step allows all following separation and treatment processes to work more efficiently. Without proper waste sizing, materials would stay entangled, making separation nearly impossible and transportation inefficient.

Shredders: Varieties and Uses for Various Waste Types

“industrial shredders” from www.hunkelersysteme.com and used with no modifications.

Shredders are the backbone of waste management, engineered to rip, slice, or pulverize materials into smaller parts. Different shredder models serve specific functions, with choice depending on waste makeup, desired output size, throughput needs, and considerations for energy efficiency. Single-shaft shredders employ a slow-spinning rotor with blades against a counter blade, making them perfect for large-scale municipal solid waste handling. Twin-shaft shredders utilize two counter-spinning shafts with interlocking cutting discs, offering superior control over output size and exceptional performance with challenging materials like tires and mattresses.

Quad-shaft shredders are for specific applications and offer an even more aggressive size reduction through four intermeshing shafts. Hammermill shredders, on the other hand, use swinging hammers to pulverize materials through impact rather than cutting. This is particularly effective for brittle materials. High-speed grinders operate at RPMs several times faster than standard shredders. They generate significant heat and require careful material selection to avoid fire risks.

Primary Shredders: These are used to reduce the size of large waste items. They operate at slow speeds (50-100 RPM) and use high torque to break down difficult materials like furniture, appliances, and mixed municipal waste.

Secondary Shredders: These machines take pre-shredded material and process it further to create smaller, more uniform particle sizes. They usually operate at medium speeds, between 100 and 250 RPM, and are often used to produce Refuse Derived Fuel (RDF) or to prepare materials for separation systems.

Fine Shredders: They produce output material of a specific size, often running at higher speeds (300+ RPM) for specialized applications like biomass fuel production or creating material for composting systems.

When choosing a shredder, it’s crucial to consider the type of material it will be processing. For unpredictable municipal solid waste (MSW), durable primary shredders equipped with contamination protection systems are the best fit. Construction and demolition waste, on the other hand, demands heavy-duty shredders with wear-resistant cutting tools that can handle concrete, wood, and metals. Electronic waste, a specialized application, requires shredders that can extract valuable components while managing dust and potentially hazardous materials.

When Should You Opt for Grinders Instead of Shredders?

“Industrial Shredders & Grinders …” from thinkviably.com and used with no modifications.

It’s common for people to use the terms grinders and shredders interchangeably. However, grinders are a unique type of size reduction equipment with distinct operational characteristics and uses. Unlike shredders, which use a cutting action, grinders typically use abrasion, impact, or crushing forces. This key difference means grinders are especially good at processing uniform waste streams where a fine particle size is needed. For more insights on processing equipment, consider comparing different types of food waste separators.

Hammer mills, a popular kind of grinder, quickly spin hammers to crush material against a screen or grate. These systems are great at processing organic materials like food waste or yard trimmings, creating a small, consistent output perfect for composting or anaerobic digestion. Vertical grinders, which are often used for wood waste processing, combine the forces of gravity with grinding elements to effectively reduce the volume of material while controlling energy consumption.

Bag Openers: Freeing Materials for Classification

“Bag Opener – MSWsorting” from www.mswsorting.com and used with no modifications.

Bag openers confront a unique yet widespread problem in waste management: reaching the contents of bagged waste for correct classification and processing. The majority of household and business waste comes to processing facilities in plastic bags, presenting an obstacle to effective materials recovery. Bag openers employ special rotating blades, hooks, or teeth intended to rip open bags while causing as little harm as possible to the contents within.

Today’s bag opening systems are designed with adjustable speed controls and load sensing technology to accommodate varying waste compositions. These high-capacity models can handle 20-60 tons per hour, making them a crucial part of large-scale MRF operations. The success of downstream separation equipment largely depends on proper bag opening, as materials that remain trapped inside bags completely avoid the sorting systems.

The Best Size Reduction Equipment for Organic Waste

Organic waste can be a challenge for size reduction equipment because it is often wet, inconsistent, and can be contaminated with non-organic materials. Slow-speed shredders with cutting systems designed to handle wet, sticky materials often work best for mixed organic streams. These systems have self-cleaning mechanisms to prevent material buildup and cutting elements that are resistant to the corrosive acids in decomposing organics. For more insights on handling organic waste, check out this comparison of different types of food waste separators.

High-speed grinders are perfect for processing clean, source-separated organics such as food waste from restaurants or grocery stores. They can produce the fine particle sizes that are ideal for speeding up biological processes. In composting applications, the perfect equipment creates particles between 1-2 inches. These are small enough for microbes to access, but large enough to maintain proper airflow through compost piles. When processing for anaerobic digestion, even finer reduction (often below 12mm) maximizes biogas production by increasing the surface area available for microbial activity. For those interested in the financial aspect, a cost analysis of food waste depackaging systems can provide valuable insights.

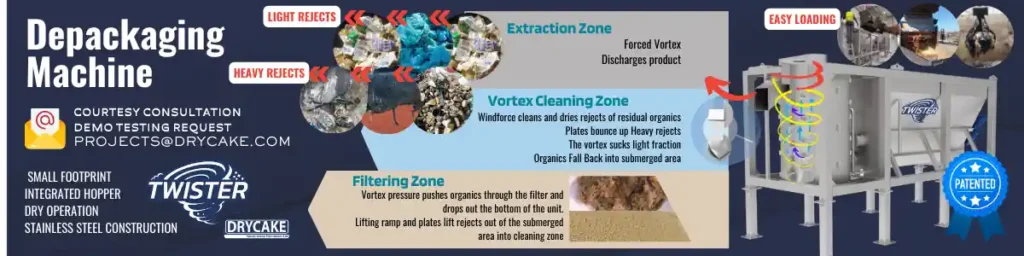

Depackaging and Separation Technologies: Making Sense of the Organic Mess

![]()

“Food Waste Separators for Depackaging …” from blog.anaerobic-digestion.com and used with no modifications.

Once the size has been reduced, separation technologies become the star of the show in waste processing. These systems use differences in material properties—size, density, magnetic properties, optical characteristics, or aerodynamic behavior—to organize mixed waste into relatively uniform streams. This effective separation is what turns “trash” into recoverable resources, allowing for the recycling principles that contemporary waste management aims to achieve.

Choosing and setting up separation equipment can greatly affect recovery rates and the quality of the final product. A separation system that’s been designed well can improve the recovery of valuable materials by 20-30% compared to basic processing. This can greatly improve the financial viability of recycling operations and lessen their impact on the environment.

For more depackaging machine suppliers and manufacturers, follow the following links:

Mavitec Green Energy Paddle Depacker Netherlands

Smicon SMIMO Depackaging Machine Waste Processing Netherlands

Doda Bio-separator Organic Waste Processing Equipment Italy

Atritor Turbo Separator Waste Processing Equipment

Scott Equipment Turbo Separator

Rowan Dominator Depackaging Machine

Drycake Twister Separator Separation Technology Canada Belgium

Anaergia OREX Organics Extrusion

Wackerbauer Food Waste Recycling Equipment Waste Processing Germany

Eurec Technology DSK Waste Processing Germany

Rothenburg MJ206 Industrial Equipment Germany

Herbold Meckesheim Recycling Technology Baden-Württemberg Germany

Screens and Sieves: The Old Faithful of Particle Size Sorting

“Screening Technology Equals “Modern-day …” from www.waste360.com and used with no modifications.

Screens are a classic and efficient method of separation in waste processing, sorting materials by particle size. Trommel screens, which are rotating perforated drums, are especially good at processing large amounts of mixed waste. The waste falls through holes of a predetermined size, while larger items continue on to the end of the drum. The continuous rotation of the drum prevents blockages and helps to break up loosely bound materials. This makes them perfect for the first stages of separation in MSW processing.

Disc screens work by using a series of rotating shafts with intermeshing discs to create a dynamic surface that stirs up material while allowing smaller particles to fall through. This design is particularly good at separating materials that might blind traditional screens, such as paper and film plastics. Vibratory screens use flat or slightly inclined screens that vibrate to move material across the surface while smaller particles fall through. These systems provide high throughput with precise sizing control, making them useful for producing specific particle size fractions for RDF production or composting.

Ballistic Separators: Separation Based on Physical Characteristics

“ballistic separator …” from www.researchgate.net and used with no modifications.

Ballistic separators are a sophisticated method for separating waste by density, shape, and size all at once. These machines use slanted, oscillating paddles to categorize materials into three different groups: rolling (3D) items such as containers, bouncing flat (2D) items like paper and cardboard, and fines that slip through the screen. The paddleboards move in an elliptical motion, causing round, heavy items to roll downward while flat, light items “climb” upward against the motion.

“Ballistic Separator | Ballistic …” from eco-tecnologie.it and used with no modifications.

Single-stream recycling operations greatly benefit from this technology, as it effectively separates containers from fiber with little need for maintenance. The latest ballistic separators feature adjustable inclination angles, stroke lengths, and screen apertures, allowing for optimal performance with different waste compositions. These versatile machines, with throughput capacities that range from 5 to 50 tons per hour, have become essential in material recovery facilities all over the world.

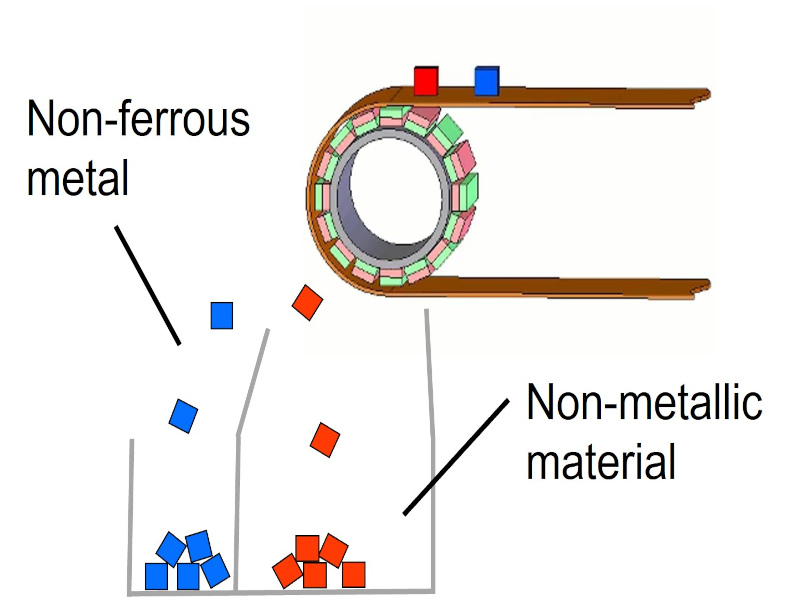

Magnetic and Eddy Current Separators: Recouping Metals

“Eddy Current Magnetic Separation | K&J …” from www.kjmagnetics.com and used with no modifications.

Recouping metals is one of the most economically beneficial aspects of waste processing, and there is specialized equipment available to extract both ferrous and non-ferrous metals from mixed waste streams. Magnetic separators use permanent or electromagnetic systems to extract ferrous metals (iron, steel) from waste streams. These systems usually use overhead magnets, magnetic head pulleys, or magnetic drums situated over conveyors to pull ferrous items from the material flow.

Eddy current separators use a high-speed rotating magnetic rotor inside a non-metallic drum to recover non-ferrous metals such as aluminum, copper, and brass. This creates a rapidly changing magnetic field that induces electrical currents within non-ferrous metals, creating a repulsive force that literally “jumps” these materials off the conveyor into a separate collection system. The combination of magnetic and eddy current separation can recover over 95% of metals from properly prepared waste streams, providing significant economic and environmental benefits.

Optical Sorting Systems: The Future of Material Sorting

“Overview of an optical sorting machine …” from www.researchgate.net and used with no modifications.

Optical sorting is the pinnacle of waste separation technology. It uses a range of sensing technologies to identify and separate materials based on their unique spectral signatures. Near-infrared (NIR) sensors can identify the molecular composition of materials. This means that these systems can tell the difference between different types of plastic (PET, HDPE, PVC, etc.) that look the same to the human eye. Once they have identified a material, they use targeted air jets to eject the material from the flow and into a dedicated collection stream. For more insights on waste separation, check out this guide on food waste separation.

Highly sophisticated optical sorters use a combination of sensing technologies. These include visible light cameras for color sorting, X-ray transmission for the identification of dense materials, and laser-induced breakdown spectroscopy for elemental analysis. These multi-sensor systems can make complex sorting decisions in milliseconds, processing up to 8 tons of material per hour per meter of belt width. Despite requiring a significant capital investment, optical sorting allows for the recovery of high-value materials with purity levels of over 95%. This meets the strict quality requirements of recycling markets.

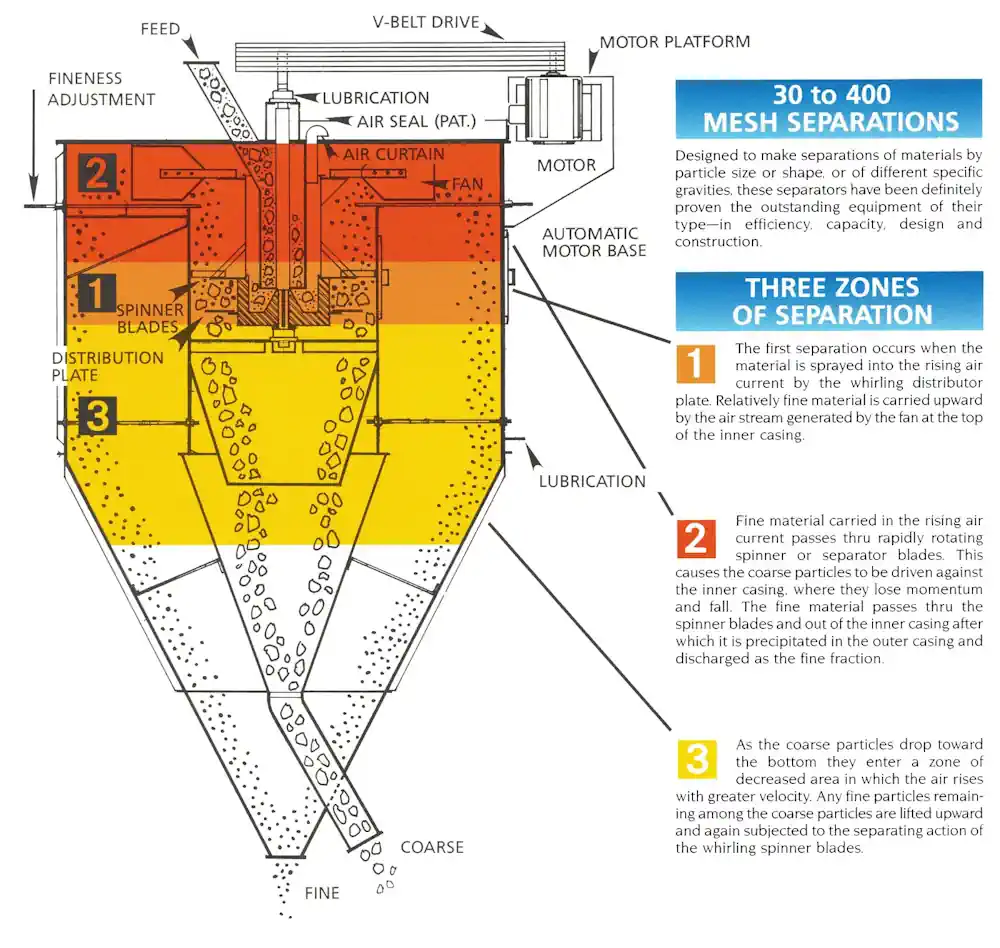

Air Classification: How it Works

“Air Classifiers & Turbine Separators …” from www.williamscrusher.com and used with no modifications.

Air classification is a process that uses aerodynamics to separate materials by weight, size, and shape. The system controls airflow through a falling waste stream. Lighter materials such as paper, plastic film, and textiles are carried upwards by the air current, while heavier items fall against it. This technology is especially useful in RDF production, as it removes heavy, non-combustible materials that would otherwise reduce the quality of the fuel.

Today’s air classifiers include adjustable airflow speeds, zigzag separation chambers, and variable feed rates to optimize performance across different waste compositions. State-of-the-art systems can achieve up to 95% separation efficiency for targeted materials when processing properly prepared feedstock. The relatively low energy consumption and maintenance requirements make air classification a cost-effective option for facilities seeking to improve material recovery without substantial capital investment.

How Density Modification Equipment Prepares Waste for Transport and Treatment

Once waste has been separated, it often needs to undergo density modification to make it easier to transport, store, or process further. These technologies are able to turn loose, bulky materials into dense, manageable forms, which can significantly cut down on handling costs and make processing more efficient. Density modification is one of the most cost-effective aspects of waste pre-treatment, often paying for itself just through the money saved on transport.

Balers: Making Recyclables More Manageable

“How Does a Vertical Baler Work?” from www.peaks-eco.com and used with no modifications.

Materials like paper, cardboard, plastics, and metals can be compressed into dense, uniform blocks with balers, making them easier to transport and store. These machines use hydraulic rams that generate 50-150 tons of pressure to reduce materials to a fraction of their original volume. Horizontal balers, the most common design for recycling applications, produce continuous extrusions that are cut into specific lengths to create uniform bales weighing between 500-2000 pounds depending on material.

Choosing the right baler involves finding a balance between the requirements for throughput, the space available, and the characteristics of the material. Materials that come in high volumes like cardboard often justify the use of auto-tie systems that automatically bind completed bales with wire or plastic strapping. On the other hand, materials that come in lower volumes and are more specialized might use manual-tie systems, which have lower capital costs. Recycling operations that deal with multiple materials often use two-ram balers. These can switch quickly between different types of materials without cross-contamination, which helps to maintain a high level of product purity.

Compactors: Shrinking Waste for Easier Transportation

“Marathon Waste Compactors & Recycling …” from dmhcompanies.com and used with no modifications.

Unlike balers, which produce individual blocks, compactors continuously compress waste within containers or transfer vehicles. Stationary compactors use hydraulic rams to compress waste into attached containers, achieving a 3:1 to 5:1 volume reduction ratio for mixed municipal solid waste. This makes them perfect for retail operations, hospitals, and other facilities that generate large volumes of general waste and need frequent waste collection.

Many transfer stations use specific compaction systems to press waste directly into transfer trailers. This ensures that the weight of the waste is within the legal limit for long-haul transport. High-tech compactors include fullness monitoring, automated cycle controls, and remote diagnostics to streamline operations and reduce the need for labor. This technology is economically beneficial because it reduces the frequency of collection and transportation costs. It also has environmental benefits because it reduces vehicle emissions.

Presses: Extracting Water from Organic Waste

“ScrewPress | Drycake” from www.drycake.com and used with no modifications.

When dealing with organic waste that contains a lot of moisture, screw presses and filter presses are the tools of choice. They work by mechanically squeezing the water out of the waste, which makes it easier to handle and process. These systems apply continuous or batch pressure to the waste, forcing the water to pass through screens or filter media. The solid fraction is retained. When food waste is processed through a screw press, it typically reduces in volume by 30-50%. The separated liquid can be used for anaerobic digestion and the solids are perfect for composting.

Food processing facilities, grocery operations, and restaurants find this technology especially useful because organic waste contains a lot of moisture. Today’s presses are self-cleaning and have variable pressure controls. They are also made of materials that resist corrosion. These materials are designed for the acidic environment created by decomposing organics. These systems reduce transportation costs and minimize leachate generation in composting operations by separating the liquid fraction early in the process. They also improve energy recovery in thermal treatment facilities.

Combining Equipment for Optimal Efficiency

While each pre-treatment technology provides its own unique advantages, the most efficient waste management facilities often combine multiple systems into one integrated processing line. These custom-engineered solutions are designed to optimize the flow of materials, maximize recovery rates, and minimize operating costs. A typical MSW processing line might start with bag opening, then move on to primary shredding, magnetic separation, screening, secondary shredding, and finally air classification. Each step builds on the previous one, progressively refining the material streams.

What exact equipment combinations you’ll need largely depends on the composition of the waste you’re handling and what you want to achieve. For example, facilities that produce refuse-derived fuel will need different configurations than those that want to maximize recycling recovery or prepare waste for biological treatment. The most successful systems are flexible and can adapt to changes in the waste stream and market conditions. They’re also modular, which means you can add or modify equipment as your needs change.

Biological Pre-treatment Systems: Getting Organics Ready for Conversion

Unlike mechanical processing, which focuses on physical separation, organic fraction pre-treatment is designed to boost biological activity. These systems ready organic materials for composting, anaerobic digestion, or other biological conversion processes by fine-tuning moisture content, particle size, nutrient balance, and contamination levels. Efficient biological pre-treatment can greatly increase biogas yields in anaerobic digestion and speed up composting times while enhancing the quality of the end product.

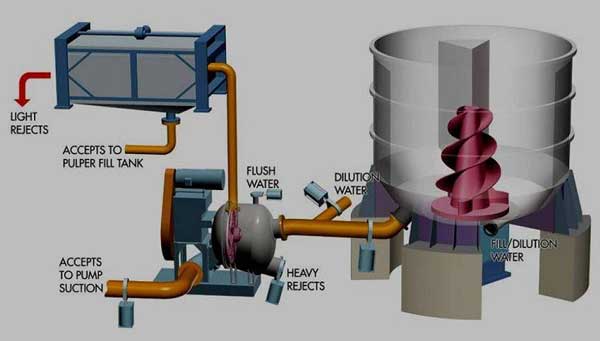

Wet Organic Waste Pulpers and Hydropulpers

“Low-Consistency Pulper | Hydrapulper …” from paperpulpingmachine.com and used with no modifications.

Food waste and other wet organics are transformed into homogeneous slurries by pulpers, which are perfect for pumping and biological processing. These systems use mechanical shearing action and water to break down organic materials, and they also separate contaminants like plastics and metals. Industrial pulpers can process up to 15 tons per hour, producing a consistent output that maximizes biogas production in anaerobic digestion systems.

Contemporary pulping systems are designed with the capacity to remove grit, depackaging, and detect foreign objects, making them well-equipped to manage the complex waste streams often found in commercial food processing. This technology is especially beneficial in institutional environments like universities and hospitals, where food waste is often mixed with serving materials that need to be separated. Pulpers convert solid organics into pumpable slurries, thus removing the need for equipment to handle solid materials in downstream processing.

Preparing Compost with Mixers and Blenders

Composting is a delicate process that requires a precise balance of carbon and nitrogen, as well as the right moisture content. This balance is essential for encouraging the growth of microbes. Specialized mixers can combine different organic materials, such as food waste, yard trimmings, and agricultural residues, to achieve this balance. Depending on the type of material and the required throughput, different types of mixers, such as horizontal paddle mixers, rotating drum blenders, and vertical auger systems, can offer unique benefits.

These systems do more than just mix. They often have the ability to add water, adjust pH by adding amendments, and reduce the size to optimize compost feedstock. Advanced compost preparation systems monitor the moisture content and material composition in real time, automatically adjusting operating parameters to maintain optimal conditions. This precise control significantly improves the efficiency of composting, reducing processing time by up to 40% compared to systems that are not optimized.

Pre-digesters for Anaerobic Digestion Systems

Pre-digestion technologies are all about making organic materials more readily available for anaerobic digestion. This greatly improves biogas yields and system throughput. These systems use thermal, chemical, enzymatic, or mechanical methods to break down complex organic structures like cellulose and lignin that are difficult to digest. Thermal hydrolysis, a popular pre-digestion technology, uses high-temperature (130-180°C) steam treatment under pressure to break open cell structures and release compounds that can be digested.

Other methods involve ultrasonic disintegration, which employs sound waves to shatter cellular structures, and enzymatic pre-treatment, which adds certain enzymes to tackle stubborn compounds. These technologies can boost biogas production by 20-50% compared to untreated feedstocks, significantly improving the profitability of anaerobic digestion facilities. Despite necessitating more capital investment, the increased energy recovery usually yields a return on investment within 2-4 years of operation.

Finding the Perfect Waste Pre-treatment Equipment for Your Needs

When it comes to picking the right pre-treatment equipment, you have to consider a variety of factors, including the type of waste, your processing goals, your budget, the amount of space you have, and any laws or regulations you need to follow. The most successful facilities start by doing a thorough waste characterization study. This study will tell you what types of materials are in the waste, how much moisture it has, how dense it is, how contaminated it is, and how it changes with the seasons. Once you have this information, you can make an informed decision about what equipment will work best for your specific waste stream.

Comparing Costs and Performance

Choosing the right equipment means weighing the initial costs against the potential benefits and savings in operation. High-tech, high-capacity systems can offer better processing, but they also require a significant investment. This investment must be justified through better recovery rates, lower operating costs, or improved product quality. A complete financial analysis should consider not only the purchase price of the equipment but also the cost of installation, any necessary changes to the facility, permitting requirements, and any possible disruption to production during implementation.

Facility Space and Integration

Physical space can often limit the types of equipment that can be used, especially when trying to retrofit existing facilities. Modern pre-treatment systems can require significant clearance heights for loading equipment, maintenance access, and material conveyance systems. Using three-dimensional facility modeling can help identify any space limitations and optimize equipment placement before installation begins.

Another crucial aspect to consider is the integration of equipment with existing systems. It is essential for new pre-treatment technologies to work flawlessly with the current processing equipment, control systems, and material handling infrastructure. The most successful implementation projects are those that include detailed transition planning, which reduces disruption to ongoing operations while guaranteeing the correct integration of new and existing systems.

Long-term Operation: Maintenance Considerations

Pre-treatment systems’ long-term viability is greatly affected by maintenance requirements. Equipment downtime can be detrimental to the operations and profitability of a facility. When selecting equipment, consider the availability of spare parts, access to service technicians, and the manufacturer’s support capabilities. The most dependable systems include preventative maintenance features. These may include automatic lubrication systems, wear monitoring sensors, and wear components that can be easily replaced. These are designed for quick servicing during scheduled maintenance periods.

Comparing Energy Use

Energy is one of the biggest ongoing costs for pre-treatment facilities, so it’s important to choose equipment that uses energy efficiently. Newer equipment often includes features designed to save energy, such as variable frequency drives, load sensing controls, and cutting geometries that have been optimized for efficiency. These features can significantly reduce the amount of power the equipment uses compared to older models. When you’re comparing different options, don’t just look at the power ratings listed on the equipment. You should also consider how much power the equipment will actually use under normal operating conditions. Many systems don’t run at full capacity during normal production. For more information on pre-treatment systems, explore RDF production pre-treatment techniques.

It’s crucial to think about the whole process energy balance, not just the direct energy use of the equipment. For instance, a shredding system that uses more energy might be worth it if it increases the efficiency of separation enough to significantly boost the recovery of valuable materials or decrease the processing issues related to contamination downstream.

What’s Next for Waste Pre-treatment: New Developments and Trends

Waste pre-treatment is a field that’s always changing, with new technologies, regulations, and market demands driving its evolution. One of the most significant trends in this sector is automation. Artificial intelligence and machine learning systems are now able to control equipment parameters in real-time based on the characteristics of the incoming waste. These intelligent systems are constantly working to optimize operation, with the goal of increasing throughput, recovery rates, and energy efficiency while reducing wear and downtime.

Improvements in sensor technology are providing never-before-seen monitoring capabilities throughout the pre-treatment process. Optical recognition systems have the ability to identify specific waste components on conveyor belts, which then triggers automated rejection mechanisms for problematic items. Moisture sensors are able to adjust process parameters for the best performance across different waste compositions, while predictive maintenance systems can identify potential equipment failures before they happen. These data-driven approaches are changing waste processing from an art to a science, providing consistent performance despite the inherently variable nature of waste materials. For more insights, you can explore food depackaging benefits as part of sustainable waste management strategies.

Common Questions

Given the intricate nature of solid waste pre-treatment equipment, it’s no surprise that facility operators, municipal planners, and waste management professionals often have a myriad of questions. Having a grasp of these frequently asked questions can aid organizations in making educated choices when it comes to selecting and utilizing pre-treatment systems.

Here are responses to the most common inquiries about solid waste pre-treatment equipment, based on industry knowledge and manufacturer recommendations.

How does a shredder differ from a grinder in waste processing?

Shredders and grinders are different in terms of their cutting action and application focus. Shredders apply shearing forces between stationary and rotating blades to rip materials apart. This makes them perfect for mixed waste streams and materials that need size reduction without precise particle control. Grinders generally use impact, abrasion, or compression forces to crush materials into fine particles with more uniform sizing. This makes them more suitable for homogeneous waste streams where consistent output size is crucial. While shredders are excellent at handling contaminated and variable materials, grinders typically achieve finer particle sizes but may be more susceptible to damage from foreign objects.

How can I tell if my facility requires a baler or a compactor?

Whether you need a baler or a compactor is largely determined by the type of material and the requirements for handling it downstream. Balers are perfect for recyclable materials that will be sold in commodity markets (such as paper, cardboard, plastics, and metals) where standard bale sizes make transport and processing easier. They create distinct, tied bundles that can be stored, stacked, and transported efficiently. For more information on setting up a waste processing facility, you can explore how to set up a food waste processing facility.

When it comes to dealing with general waste streams that are headed for disposal, compactors are usually the better option. These machines create continuous compression inside collection containers or transfer vehicles. They can usually achieve a higher density for mixed municipal solid waste and they don’t need a person to manage their output. If a facility is producing large volumes of both recyclables and general waste, the best solution is often a combination of both technologies. For those dealing with food waste, exploring different types of food waste separators can be beneficial.

Is pre-treatment equipment capable of processing both dry and wet organic waste?

Most organic pre-treatment systems are designed to handle specific moisture content ranges, and there can be significant differences in performance between equipment designed for wet materials and those designed for dry materials. High-moisture organics such as food waste and biosolids typically require specialized equipment that has self-cleaning features, corrosion-resistant components, and the ability to manage liquids. These systems often include screw presses or dewatering stages to deal with the large amount of liquid.

Equipment used in dry organics processing, such as yard waste and woody materials, is more focused on reducing size and removing contamination rather than managing moisture. For facilities that process both wet and dry organics, the most effective solution is often a two-stage system or parallel processing lines. This allows each type of material to be appropriately treated before they are combined for final processing.

What is the best maintenance schedule for waste shredders?

The best maintenance for shredders includes both time-based and condition-based schedules. The requirements can differ greatly depending on the equipment design and waste composition. Daily inspections should include checking the cutting tools for any damage, checking the hydraulic systems for any leaks, and making sure the safety systems are working properly. Weekly maintenance should usually include greasing the bearings, checking the tension of the belts, and cleaning any material buildup from critical areas. Monthly or quarterly services should include a more comprehensive inspection of the drive components, a hydraulic fluid analysis, and measuring the wear rates of the cutting tools to plan when to replace them.

How does pre-treatment equipment boost recycling?

Pre-treatment equipment boosts recycling in several ways. Size reduction frees materials that would otherwise stay stuck together, making it possible to separate them. Screening and classification systems then divide these materials into specific streams that can be recycled efficiently. Advanced technologies like optical sorting recover valuable materials that manual sorting would miss, while density modification equipment creates products that can be sold and meet industry standards. Together, these processes can increase material recovery by 30-50% compared to basic collection and manual sorting methods.

Pre-treatment goes beyond just physical separation. It also improves the economics of recycling by reducing contamination levels and creating consistent, high-quality material streams. These streams can command premium prices in recycling markets. This economic advantage makes it financially sustainable to have higher recycling rates. Facilities can divert more materials from disposal while still maintaining operational viability.

Properly selected pre-treatment equipment can turn a waste disposal operation into a resource recovery system that can extract value from materials that would otherwise be destined for a landfill. Every piece of technology, from basic size reduction to sophisticated optical sorting, contributes to the vision of a circular economy, where today’s waste becomes tomorrow’s resources.

Facilities aiming to increase recovery rates, lessen environmental damage, and improve operational costs should consider investing in suitable pre-treatment equipment. This is more than just a technical choice; it’s a strategic pledge to managing materials sustainably.

Checklist for Selecting Pre-Treatment Equipment

- Comprehensive analysis of waste composition (including changes in seasons)

- Clear definition of processing objectives and the required output specifications

- Realistic throughput requirements with room for growth

- Available space measurements and limitations

- Budget parameters for capital and operational costs

- Local regulatory requirements and permit considerations

- Availability of qualified maintenance personnel

- Integration requirements with existing systems

Understanding the full range of pre-treatment technologies allows waste management professionals to create integrated systems that turn difficult waste streams into valuable resources. As regulatory pressures increase and disposal costs rise, effective pre-treatment becomes not only environmentally responsible but also economically necessary.

If you need advice on choosing and using the best solid waste pre-treatment equipment for your unique requirements, get in touch with the waste processing professionals at GEP ECOTECH. They have years of experience in creating and producing extensive waste management solutions and can help you get the most from your resources while reducing your environmental footprint.